Sawmills & Lumber

CryoPlus is an authorized dealer of Simonds knives!

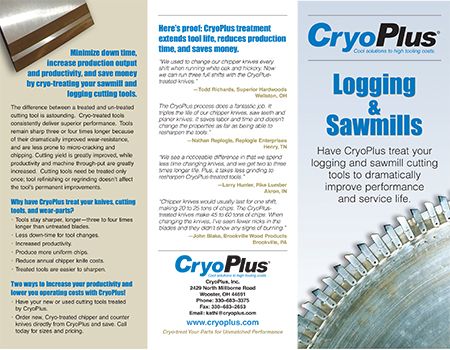

Our cryogenically treated chipper knives are exceptionally tough and durable. Made of special steel alloy, these chipper knives are heat treated to stand up under the heaviest feed possible. They produce uniform chips and reduce fines to an absolute minimum. Their “cryo treated” durability increases production, saves grinding time and decreases your yearly use of chipper knives.

Major sawmill customers:

- Knox Hardwoods

- Patterson Chip

- DeNoone Lumber

- Mohawk Lumber

- Pike Lumber

- Replogle

- Brookville Wood Products

- Bruce Hardwood

- PalletOne of Indiana

View Our Brochure

| Simonds Knives | |

|---|---|

| 48" Counter knives | Call for pricing |

| 58" Counter knives | Call for pricing |

| 60" Counter knives | Call for pricing |

| 48" Precision, Combination (#24977) (14 3/4" x 4" x 3/8") | Call for pricing |

| 58" Precision, Combination (#25027) (19 5/8" x 4" x 3/8") | Call for pricing |

| 60" Fulghum, Combination (#24972) (19 1/4" x 4" x 3/8") | Call for pricing |

| 66" Precision, Combination (#25075) (21 1/2" x 3 15/16" x 3/8") | Call for pricing |

Testimonials

“It does a fantastic job," he comments. The cryo process triples the life of his chipper knives, saw teeth and planer knives. "It saves labor and time and doesn't change the properties as far as being able to resharpen the tools.”

“Noticeable difference in wear. Less time changing knives.2 to 3 times longer life. Less grinding to resharpen.”

“Chipper knives would usually last for one shift which would make 20-25 tons of chips. The cryo treated knives made 45-60 tons of chips. When changing the knives I've seen fewer nicks in the blades and they didn't show any signs of burning.”