The Story

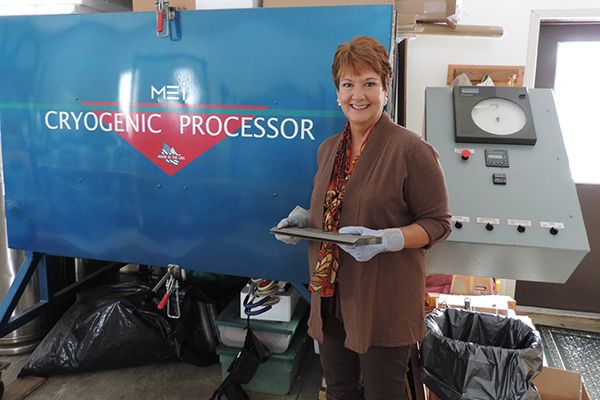

Kathi Bond founded CryoPlus, Inc. in 1994 to provide cryogenic services to a multitude of industries, including: wood working (forestry/chipping/planing/moulding/cabinetry), metal working (tooling/cutting tools/slitting/punching/cold forming/shearing/sawing), musical instruments and components, and motor sports. CryoPlus quickly grew and was soon well-recognized at a national level. As her retirement drew near, Kathi personally selected WRN Technical Solutions as the group to continue her success. WRN, a multi-disciplined engineering firm providing custom machinery design and build services to manufacturers across multiple industries, continues to follow Kathi’s history of providing rapid order turn-around, many stock items, and overall superb customer service to clients needing cryogenically treated parts. Kathi Bond continues to provide consultation and knowhow to assure all client’s expectations are exceeded!

Learn More

The Process

The processor utilizes the cooling capacity of liquid nitrogen in a batch process that is controlled by a microprocessor. Liquid nitrogen flows through a sophisticated spray distribution system inside the chamber as it vaporizes. The chamber’s circulation fan ensures proper thermal transfer during the vaporization process. The system is designed to thermally treat parts down to -300°F as well as heat materials up to +350°F.

Learn More

The Advantages

Improve performance and increase the life up to 400% of metal cutting tools, blades, knives, stamping dies, shears, punches, engine components, baseball bats and golf club heads with cryogenic processing. The process of deep freezing metal parts makes the internal structure more uniform, durable and stronger. The net result for the customer is lower manufacturing costs and superior product performance.

Learn More